Experts in Medical-Grade Heat Shrink Tubing

Why Pebax & Polyolefin?

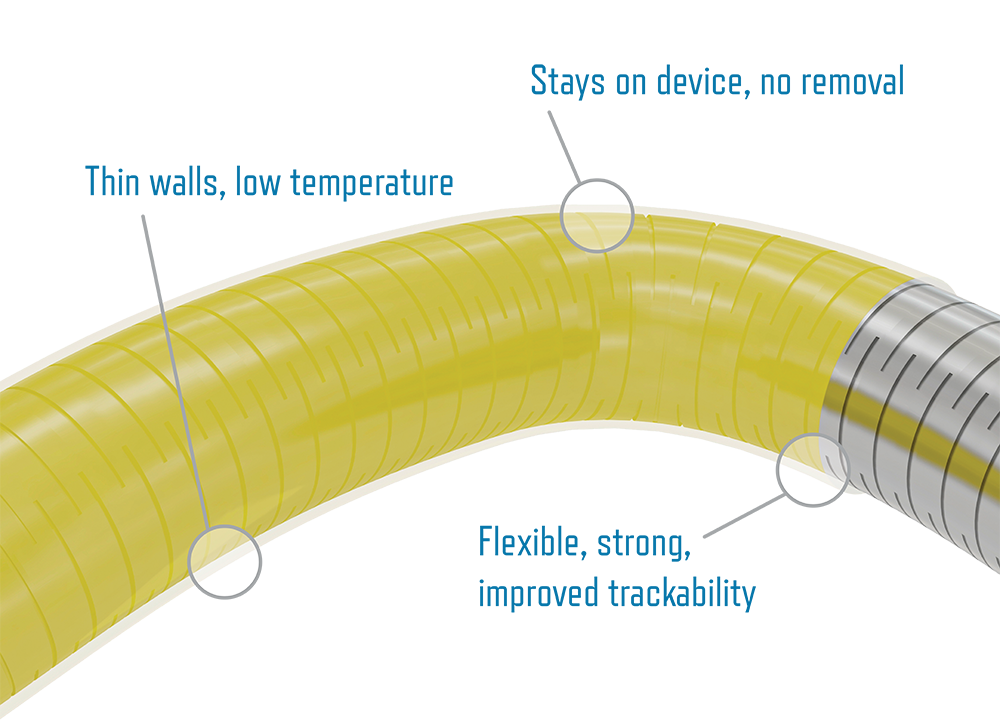

These Class VI materials:

Work well for applications that need thin walls and low-temperature shrink

Offer flexible tubing with improved trackability—without sacrificing strength

Can stay on your device without a cumbersome removal process

When flexibility matters:

Which material is best for your application?

Pebax Heat Shrink Tubing

Unique heat shrink tubing invented by Cobalt Polymers

This flexible, thin, durable, and compatible material gives you maximum adherence to polymers and metals

Flexible

Thin

Durable

Medical grade

High shrink ratio

Low shrink temperature (~340° F)

Class VI material

Highly compatible; maximum adherence to polymers and metals

Remains on device; eliminates cumbersome removal and reflow processes

Ideal for applications that need a uniform outer jacket, including catheter & guidewire fabrication and encapsulation

Polyolefin Heat Shrink

Tubing

Not your father’s Polyolefin

This medical-grade polyolefin is flexible, thin, and has high compressive strength, making it ideal for electrical insulation and strain relief

Flexible

Thin

Durable

Medical grade

High shrink ratio

Very low shrink temperature (~220° F)

Class VI material

High compressive strength

Can remain on device or be removed

Ideal applications include electrical insulation and strain relief

Ready to try it?

Get Advice

Wondering what tubing is best for your application?

Request advice from our technical team to identify the right tubing

Samples

Small Quantities

New to Cobalt Polymers and want to try our tubing?

Try a sample to see if it’s a good fit for your project

Tried our tubing and ready

to order more?

Order small quantities of in-stock, quick-ship tubing for prototypes on Chamfr.com

Get a Quote

Already know what you need?

Fill out a Request for Quote form for the fastest response

Component Criteria

These pages are password protected. To request password, please email us or call (800) 337-0901.